Alloy 625 Alagbara Irin Coil Tubing Price

Iṣọkan Kemikali,%

Ohun elo Alloy 625 kii ṣe oofa, austenitic, ati ṣafihan agbara fifẹ giga, iṣelọpọ, ati brazeability.Nitori akoonu nickel ti o ga, alloy yii fẹrẹ jẹ ajesara si chloride ion wahala-ipata fifọ ati pitting, eyiti a rii ni igbagbogbo ni awọn irin ni awọn ohun elo omi okun bi awọn paarọ ooru, awọn finnifinni, ati ohun elo okun.

| Cr | Ni | Mo | Co + Nb | Ta | Al | Ti | C |

| 20.00-30.00 | Iyokù | 8.0-10.0 | 1.0 ti o pọju | 3.15-4.15 | .40 o pọju | .40 o pọju | .10 o pọju |

| Fe | Mn | Si | P | S |

| 5.0 ti o pọju | .50 o pọju | .50 o pọju | 015 o pọju | 015 o pọju |

Ninu awọn ohun elo wo ni a lo Inconel 625?

- Inconel 625 jẹ lilo ni akọkọ ni ile-iṣẹ Aerospace

- Ofurufu ducting awọn ọna šiše

- Jet engine eefi awọn ọna šiše

- Awọn ọna ẹrọ ifasilẹ-iyipada

- Specialized okun ẹrọ

- Awọn ẹrọ ilana ilana kemikali

ASTM Awọn pato

| paipu Smls | Pipe Welded | Tube Smls | Tube Welded | Dì / Awo | Pẹpẹ | Ṣiṣẹda | Ni ibamu | Waya |

| B444 | B705 | B444 | B704 | B443 | B446 | - | - | - |

Darí Properties

| Iwọn otutu ° F | Fifẹ (psi) | .2% Ikore (psi) | Ilọsiwaju ni 2 "(%) |

| 70 | 144,000 | 84,000 | 44 |

| 400 | 134,000 | 66,000 | 45 |

| 600 | 132,000 | 63,000 | 42.5 |

| 800 | 131.500 | 61.000 | 45 |

| 1000 | 130,000 | 60.500 | 48 |

| 1200 | 119,000 | 60,000 | 34 |

| 1400 | 78.000 | 58.500 | 59 |

| 1600 | 40,000 | 39.000 | 117 |

Inconel 625 Melting Point

| Ojuami Iyo | 1290 - 1350 °C | 2350 - 2460 °F |

Inconel 625 deede

| ITOJU | WORKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Inconel 625 | 2.4856 | N06625 | NCF 625 | NÁÀ 21 | ХН75МБТЮ | NC22DNB4MNiCr22Mo9Nb | NiCr23Fe |

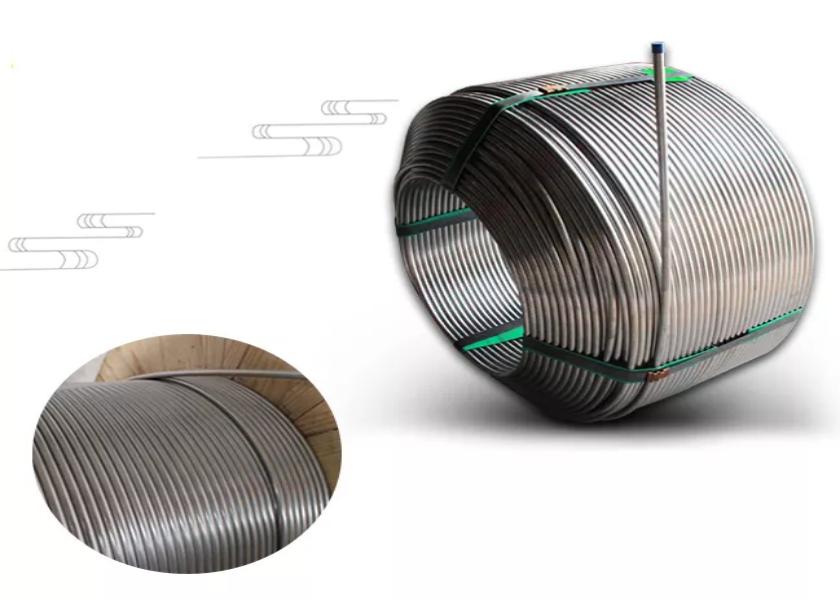

Alloy 625 Tubing

Alloy 625 jẹ austenitic nickel-chromium-molybdenum superalloy ti a mọ fun jija si ipata crevice ati ifoyina ni awọn iwọn otutu ti o ga.Awọn iwọn otutu wọnyi le wa lati cryogenic si awọn ipele ti o gbona pupọju ti 1,800°F.Ihuwasi ati akojọpọ kẹmika ti ipele yii jẹ ki o baamu daradara fun awọn ohun elo iparun ati aerospace.Pẹlupẹlu, pẹlu afikun ti niobium, alloy 625 tubing wa ara rẹ pẹlu agbara ti o pọ si laisi itọju ooru.Ohun-ini yii jẹ ki ite jẹ aṣayan ti o tayọ fun iṣelọpọ.

Awọn pato ọja

ASTM B444 / ASME SB444 / NACE MR0175

Iwọn Iwọn

| Opin ita (OD) | Sisanra Odi |

| .375"–.750" | .035”–.095” |

Awọn ibeere Kemikali

Alloy 625 (UNS N06625)

Àkópọ̀%

| C Erogba | Mn Manganese | Si Silikoni | P phosphorous | Cr Chromium | Nb+Ta Niobium-Tantalum | Co Kobalti | Mo Molybdenum | Fe Irin | Al Aluminiomu | Ti Titanium | Ni Nickel |

| 0.10 ti o pọju | 0.50 ti o pọju | 0.50 ti o pọju | ti o pọju 0.015 | 20.0-23.0 | 3.15–4.15 | 1.0 ti o pọju | 8.0-10.0 | 5.0 ti o pọju | 0.40 ti o pọju | 0.40 ti o pọju | 58.0 iṣẹju |

Onisẹpo Tolerances

| OD | Ifarada OD | Ifarada Odi |

| .375"-0.500" iyasoto | + .004”/-.000” | ± 10% |

| 0.500"-1.250" iyasoto | + .005”/-.000” | ± 10% |

Darí Properties

| Agbara ikore: | 60 ksi min |

| Agbara fifẹ: | 120 ksi min |

| Ilọsiwaju (iṣẹju 2): | 30% |

Awọn fọto Factory

Ayewo

Gbigbe & Iṣakojọpọ

Iroyin igbeyewo